مكان المنشأ: |

تشيان |

اسم العلامة التجارية: |

آ-دونغ |

رقم الطراز: |

941006/123x27 |

الشهادة: |

ISO9001/ CE /ROSH |

كمية الطلب الأدنى: |

300 |

السعر: |

73RMB |

تفاصيل التغليف: |

كرتون قياسي |

وقت التسليم: |

شهر واحد / في أي وقت |

شروط الدفع: |

30% مقدم، 70% دفع عند الاستلام |

قدرة التوريد: |

20000 قطعة/شهر |

ремيز PTFE (تفلون) يشير إلى حزام توقيت السيارة المطلي بمادة PTFE أو المصنوع من قماش يحتوي على تفلون. في الظروف العادية، تكون الألوان المتاحة باللون الأسود والأبيض، والتي لا تؤثر على استخدامه. في الظروف العادية، يكون عمر الخدمة عادةً من 80000 إلى 100000 كيلومتر، أو من 4 إلى 6 سنوات.

كم مدة استخدام أحزمة PTFE

يجب تقييم عمر أحزمة التوقيت PTFE بشكل شامل بناءً على تكنولوجيا المواد والبيئة المستخدمة وظروف الصيانة. في الظروف العادية، يكون عمر الخدمة عمومًا من 60000 إلى 100000 كيلومتر، أو من 4 إلى 6 سنوات، ويمكن أن تتأثر بعوامل التالية:

1. اختلافات في عملية المنتج:

ремيز A-DONG لتفلون أحزمة التوقيت تستخدم عادةً مواد خام عالية الجودة (مثل حبال الألياف الزجاجية، أجسام من المطاط الكلوروبريني/مطاط النيتريل المُشبَّع) مدمجة مع طلاءات من مادة PTFE لصناعة أحزمة التوقيت من نوع PTFE، مما يمنحها مقاومة أكثر استقراراً للتآكل ومقاومة عالية للحرارة، مع عمر افتراضي يصل إلى 80,000 حتى 100,000 كيلومتر (على سبيل المثال، أحزمة توقيت PTFE من سلسلة Daigo HT المصممة للمحركات المزودة بشواحن توربينية، حيث تم تصميمها لزيادة العمر الافتراضي بنسبة تصل إلى 30% مقارنة بالأحزمة العادية).

قد يؤدي استخدام منتجات ذات جودة منخفضة إلى تقليل العمر الافتراضي إلى 40000 - 60000 كيلومتر بسبب ضعف التصاق طبقة الطلاء من مادة PTFE وعدم كفاية قوة المادة الأساسية، وقد تظهر أيضًا مشاكل مثل التشقق المبكر والانزلاق وغيرها.

2. التأثير البيئي أثناء الاستخدام:

إذا تم استخدام المركبة لفترة طويلة في بيئات ذات درجة حرارة عالية وغبارية (مثل المناطق الاستوائية والطرق الصحراوية)، أو إذا كان قسم المحرك يعاني من ختم ضعيف وتسرب زيت/سائل التبريد ويأتي في تلامس مع الحزام، فسوف يسرع ذلك من الشيخوخة الطبقة الطلائية من مادة PTFE والتآكل المعدني، وقد تقل مدة الخدمة بنسبة تتراوح بين 20٪ إلى 30٪.

على العكس من ذلك، يؤدي تنظيف قسم المحرك بانتظام والحفاظ على جفاف الأحزمة ونظافتها إلى إطالة عمرها الافتراضي.

3. الصيانة والملاءمة مع ظروف العمل:

إن التوتر غير الطبيعي لحزام التوقيت (مترهلًا جدًا أو مشدودًا جدًا)، وتآكل البكرة، وما إلى ذلك، يمكن أن يزيد من تآكل الحزام، ويجب إجراء فحص دوري وفقًا لدليل المركبة (عادةً كل 20000 كيلومتر).

يصلح حزام توقيت التفلون أكثر لظروف التحميل العالي (مثل المحركات ذات الشاحن التوربيني، والتشغيل والإيقاف المتكرر)، وإذا استُخدم في محركات عادية ذات تحميل منخفض مع صيانة مناسبة، فإن عمره الافتراضي يمكن أن يقترب من الحد الأعلى؛ وإذا كانت ظروف التشغيل غير ملائمة (مثل الاستخدام في محركات ضغط عالٍ جداً)، فقد يفشل مبكراً بسبب الحمل الزائد.

التوصية: يرجى الرجوع إلى دليل الصيانة المُقدَّم من مصنّع المركبة (والذي سيحدد دورة استبدال حزام التوقيت، عادةً ما تكون مماثلة أو أطول قليلاً من أحزمة التوقيت العادية). في الوقت نفسه، يُوصى باختيار منتجات من علامات تجارية معروفة، وإجراء فحص دوري لحالة الحزام على يد أشخاص محترفين (مثل وجود شقوق، اهتراء الأسنان، تقشر الطلاء، إلخ) لتجنب تعطل المحرك الناتج عن فشل حزام التوقيت.

ما هي الاستخدامات الرئيسية لأحزمة PTFE من العلامة التجارية A-DONG في السيارات

تُستخدم أحزمة توقيت PTFE (Teflon) من علامة A-DONG التجارية في كثير من الأحيان كقطع أصلية أو قطع تبديل في السوق الثانوي من قِبل العديد من العلامات التجارية الشهيرة مثل Alfa Romeo وVolkswagen وFord إلخ

|

النوع |

العلامة التجارية |

OE |

شكل السن |

|

123RP270H

|

نيسان |

13028-BN700 |

|

|

نيسان |

13028-BN701 |

||

|

نيسان |

16806-00QA2 |

||

|

نيسان |

16806-00QAZ |

||

|

نيسان |

16806-00QBC |

||

|

نيسان |

16806-00QBE |

||

|

نيسان |

82000-39519 |

||

|

رينو |

8200241629 |

||

|

رينو |

8200344791 |

||

|

رينو |

8200366318 |

||

|

رينو |

8200508612 |

||

|

رينو |

8200537033 |

لماذا تختار بوليمر (PTFE) (الفلون) المتزامن حزام

1. معامل الاحتكاك المنخفض (≈ 0.02-0.1)

معامل الاحتكاك لـ PTFE السطح منخفض للغاية، حوالي 1/5-1/10 من المطاط العادي. عندما تلامس الحزام البكرة، يمكن تقليل الاحتكاك والبلى الناتج عن الانزلاق بشكل كبير - مما يمنع الحزام من التسخين المفرط والشيخوخة الناتجة عن الاحتكاك، كما يقلل من فقدان الطاقة أثناء التشغيل (تقليل ظاهرة "الانزلاق")، مما يجعل نقل الطاقة أكثر كفاءة.

2. مقاومة عالية للحرارة والاستقرار الكيميائي

يمكن لتفلون تحمل درجات حرارة تتراوح بين -200 درجة مئوية إلى 260 درجة مئوية لفترة طويلة، ويتفاعل بشكل ضئيل جداً مع مواد كيميائية مثل زيت المحرك والوقود وسائل التبريد. في بيئة درجات الحرارة العالية (عادةً 80-120 درجة مئوية) وتسرب الزيت المتقطع داخل غرفة المحرك، لا يلين أو يتشقق أو يتأكل الطلاء أو الطبقة الأساسية بسهولة، مما يحافظ على قوة البنية واستقرار الأبعاد للحزام.

3. خصائص مقاومة اللصوق والتنظيف الذاتي

إن سطح مادة PTFE لا يلتصق به الغبار أو الزيت أو الحطام بسهولة، مما يقلل من عدم التوازن الديناميكي الناتج عن "الالتصاق" الحزام (ومن ثم تجنب الاهتزازات الناتجة عن الوزن غير المتوازن أثناء التشغيل)، كما يمنع دخول الشوائب إلى فجوة التشابك بين أسنان الحزام والبكرة، مما يضمن دقة النقل (ويعد هذا الأمر بالغ الأهمية بالنسبة لحزام التوقيت الذي يتطلب توافقًا دقيقًا بين سرعة عمود المرفق وعمود الكامات).

2، مبدأ النقل الأساسي للحزام (متماشيًا مع حزام التوقيت العادي)

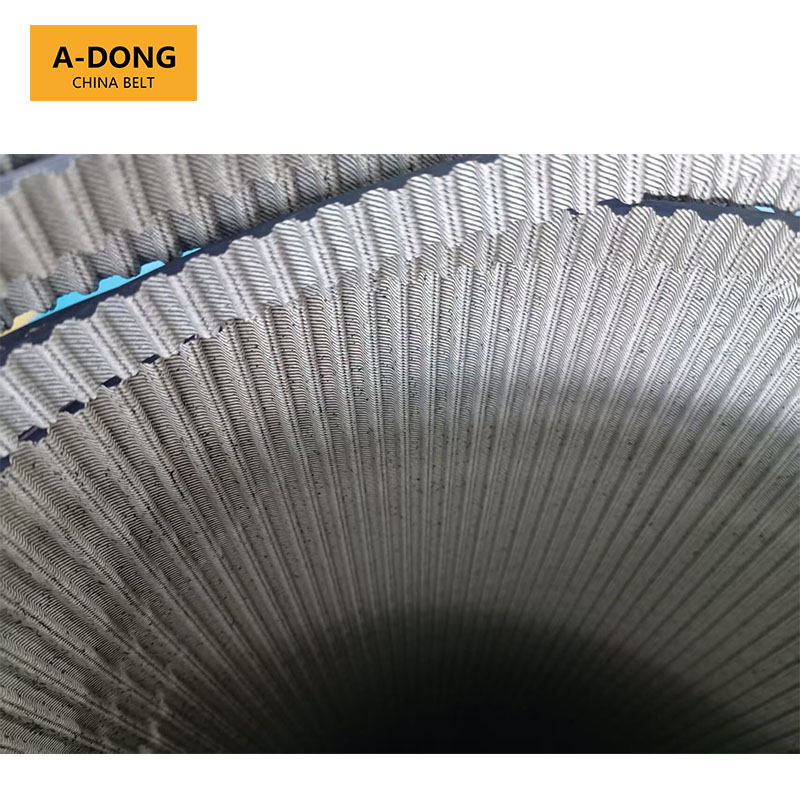

لا يزال الهيكل الرئيسي لحزام PTFE يتبع مبدأ "النقل بالتمشيط المسنن":

الجهة الداخلية للحزام تحتوي على أسنان موزعة بشكل متساوٍ، وتتصل بدقة مع الأخاديد الموجودة على بكرة عمود المرفق وبكرة عمود الكامات في المحرك.

عندما يدور عمود المرفق، يتم "نقل القوة بشكل متزامن" إلى عمود الكامات من خلال تشابك بكرة الحزام وأسنانه، مما يؤدي إلى فتح وغلق الصمامات في الوقت المناسب (وهي الوظيفة الأساسية لحزام التوقيت).

لم تغيير إضافة مادة التفلون من تركيب نقل الحركة، ولكنها عالجت عيوب الأحزمة المطاطية العادية (مثل المطاط الكلوروبرين) من حيث الاحتكاك ومقاومة الحرارة والمقاومة للتآكل من خلال تحسين خصائص المادة، مما جعل نقل الحركة بالتداخل أكثر استقرارًا وأطول عمرًا افتراضيًا.

باختصار، مبدأ أحزمة البولي تيترافلورو إيثيلين (PTFE) هو تحسين ظروف التشغيل باستخدام خصائص هذه المادة، وتحقيق نقل للقوة من خلال هيكل مسنن متداخل. الجمع بين هذين العاملين يجعلها أكثر ملاءمة للبيئة المعقدة داخل غرفة المحرك، خاصة لمتطلبات النقل الدقيق في ظل ظروف الأحمال والحرارة العالية.

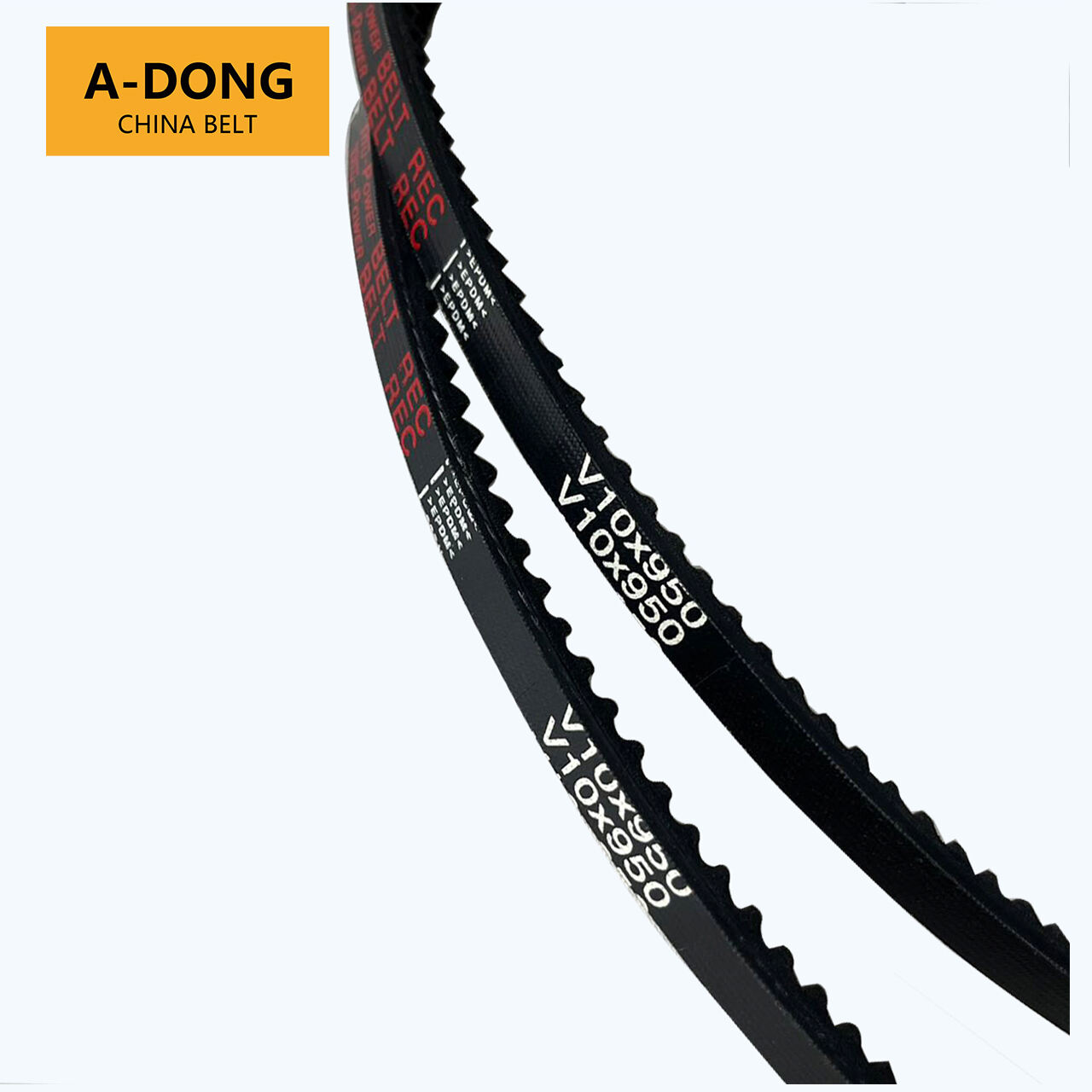

حزام نقل V-belt كهربائي فعال 13X900LA بأسنان مطاطية لنقل الحركة بالتروس، حزام الدينامو

80000 كم أحزمة بولي-في متعددة التجويفات عالية الجودة، أحزمة بولي-في/ أحزمة دقيقة ذات تجويفات صغيرة وأحزمة سير حزامية - مصنع في الصين/خدمة تصنيع المعدات الأصلية

حزام توقيت تفلون/الموديل 941006 123RP270H HNBR+تفلون لمحرك الديزل

حزام توقيت بدون ضوضاء، أنواع مختلفة من أسنان الحزام، لحماية محركات السيارات، مواد HNBR/CR من مصنع في الصين