Place of Origin: |

China |

Brand Name: |

A-DONG |

Model Number: |

OEM |

Material: |

Rubber |

Application: |

Power Transimission |

Advantage: |

Strong Tensile Resistance |

Feature: |

High Transmission Efficiency |

Quality |

High Level |

Minimum Order Quantity: |

100pcs |

Price: |

1.15$ |

Packaging Details: |

Will ACCORDING TO CUSTOMER REQUIREMENT. |

Delivery Time: |

WITHIN 25 DAYS AFTER RECEIVED THE DEPOSIT. |

Payment Terms: |

30%T/T IN ADVANCED ,THE BALANCE WILL BE PAID BEFORE SEND THE PRODUCTS TO WAREHOUSE |

Supply Ability: |

High quality, capable, and factory based suppliers |

Engine Valve Timing ControlIt ensures the intake and exhaust valves open and close at the precise moment relative to the piston's position, which is critical for optimal engine performance, fuel efficiency, and reducing emissions.

Power Transmission for Auxiliary ComponentsIn some engine designs, the timing belt also drives additional parts besides camshafts, such as water pumps, balance shafts, or oil pumps, integrating multiple functions into one drive system.

High-Performance and Lightweight EnginesIt is commonly used in high-revving engines (like those in sports cars) and lightweight vehicle engines. This is because it operates with less noise, lower inertia, and more precise synchronization compared to timing chains.

|

Model |

Pitch (mm) |

Belt Height(mm) |

Tooth Height(mm) |

|

ZA |

9.525 |

4.1 |

1.9140 |

|

ZB |

9.525 |

4.5 |

2.29 |

|

(Y)MY |

8 |

5.21 |

3.11 |

|

(R)MR |

9.525 |

5.69 |

3.54 |

|

ZD |

9.525 |

5.5 |

3.5 |

|

RPP |

9.525 |

4.5 |

2.25 |

|

ZBS |

9.525 |

5.1 |

2.8 |

|

S8M |

8 |

5.3 |

3.05 |

|

ZAS |

9.525 |

4.62 |

2.32 |

|

RU |

9.525 |

5.7 |

3.56 |

|

YU |

8 |

5.2 |

3.109 |

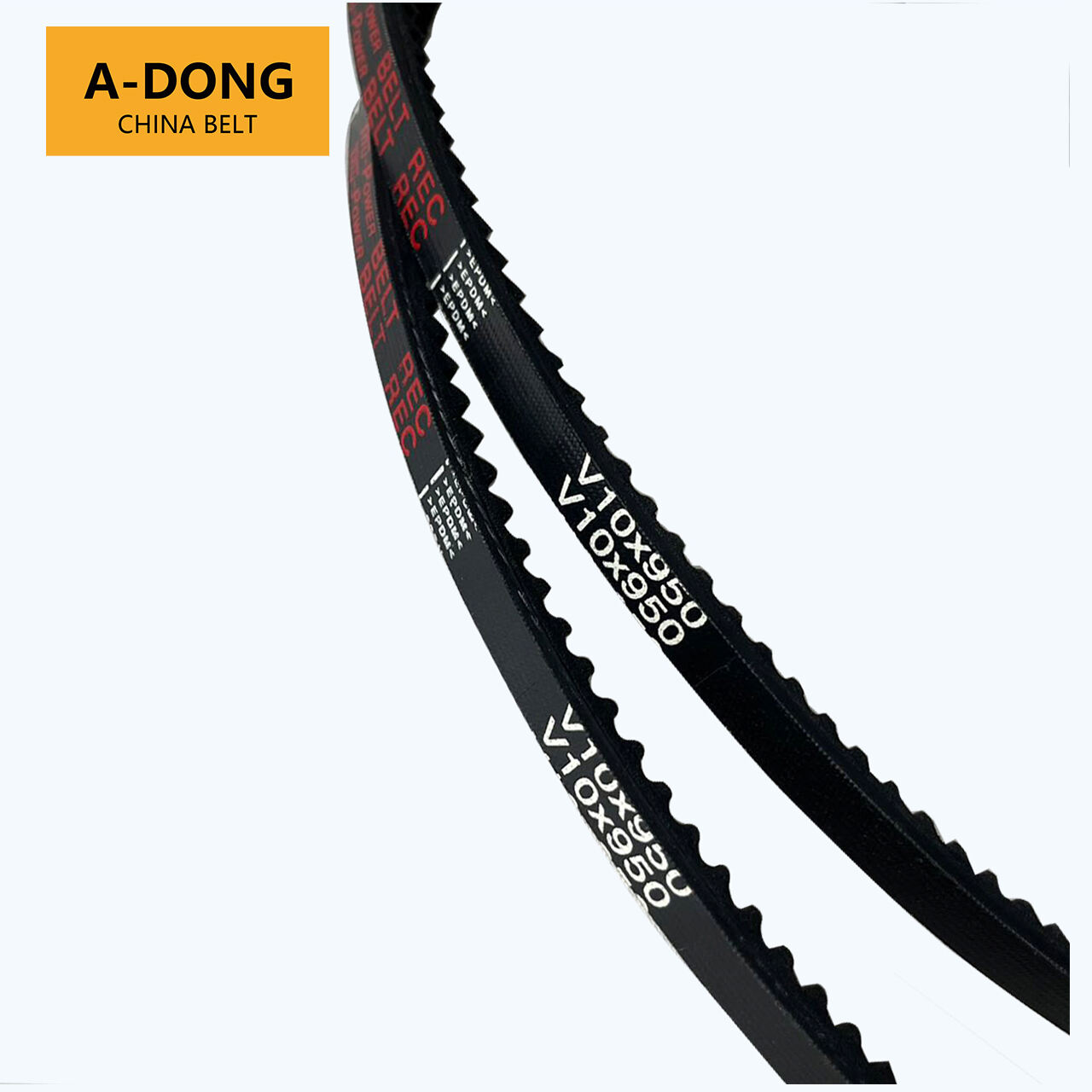

Title:Engine equipment Toothed Auto Parts Timing Belt Rubber With Fiberglass White/black

Primarily used in gasoline and diesel internal combustion engines for passenger cars, light trucks, motorcycles, and some industrial machinery.

In some engine designs, it may also drive auxiliary components like water pumps, balance shafts, or oil pumps to simplify the engine’s drive system.

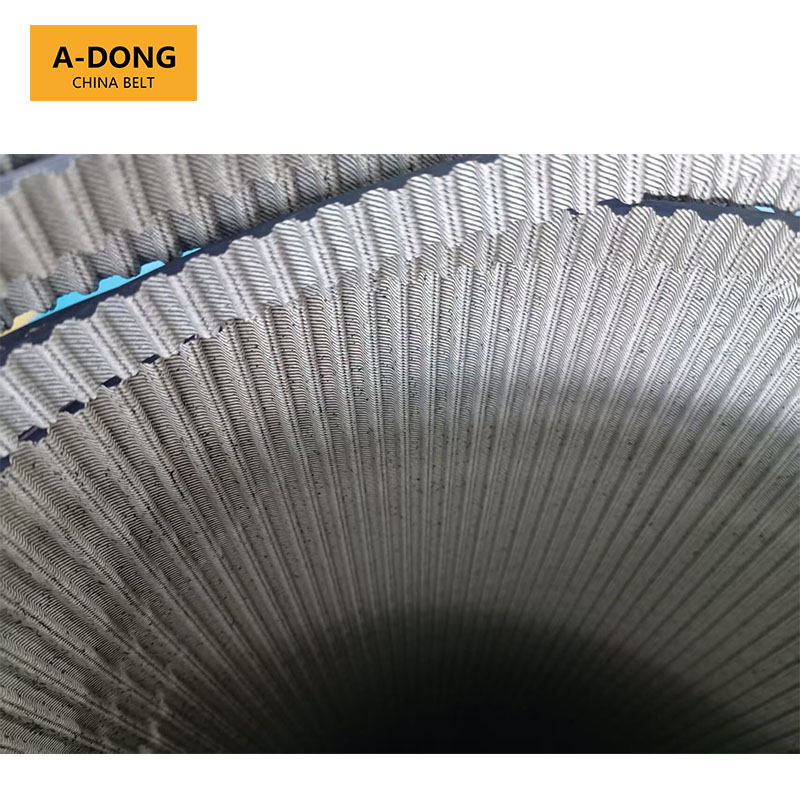

A: Good heat resistance--can work on the 120 C high temperature long time.

B:Good aging resistance--ozone resistance

C:Good chemical stability:except strong oxidative acid, resistant to general chemicals

D:Good flame&water resistance

A:Excellent Oil resistance-- low oil - resistant expansibility

B:Good durability--Dynamic performance is better than the CR timing belt,mainly used on the first&mid-grade car.

C:Excellent wear resistance--Abrasion quantity is small than CR timing belt ,reduce the noise,extended the life of timing belt effectively.

The core application of the timing belt is to synchronize the operation of key components in the engine and, in some designs, drive auxiliary systems.

1. Engine core: Synchronization of crankshaft and camshaft

This is the most fundamental and crucial application of the timing belt.

It connects the crankshaft (which drives the piston movement) and the camshaft (which controls the opening and closing of intake and exhaust valves) in the engine.

By precisely synchronizing the rotational speeds of the two, it ensures that the valves open or close when the piston is in the correct position (such as at the top of the compression stroke or at the end of the exhaust stroke), preventing valve-piston collisions and ensuring normal engine intake, compression, power generation, and exhaust.

2. Driving engine auxiliary components

Some engine designs utilize the timing belt to drive other key components simultaneously, simplifying the transmission system.

Water pump: Responsible for circulating coolant to cool the engine and prevent overheating.

Balance shaft: Counteracts vibrations generated during engine operation, enhancing ride smoothness and engine lifespan.

Oil pump: Delivers oil to the engine's friction components, providing lubrication and cooling.

3. Adaptation to specific engine types

The characteristics of the timing belt make it a preferred choice in certain scenarios.

High-revving engines: Such as in sports cars or motorcycle engines, its low inertia and low noise features can better accommodate high-speed operation, ensuring timing accuracy.

Lightweight engines: Compared to metal timing chains, the rubber timing belt is lighter, helping to reduce the overall weight of the engine and improve vehicle fuel economy.

|

Model |

Pitch (mm) |

Belt Height(mm) |

Tooth Height(mm) |

|

ZA |

9.525 |

4.1 |

1.9140 |

|

ZB |

9.525 |

4.5 |

2.29 |

|

(Y)MY |

8 |

5.21 |

3.11 |

|

(R)MR |

9.525 |

5.69 |

3.54 |

|

ZD |

9.525 |

5.5 |

3.5 |

|

RPP |

9.525 |

4.5 |

2.25 |

|

ZBS |

9.525 |

5.1 |

2.8 |

|

S8M |

8 |

5.3 |

3.05 |

|

ZAS |

9.525 |

4.62 |

2.32 |

|

RU |

9.525 |

5.7 |

3.56 |

|

YU |

8 |

5.2 |

3.109 |

Generator Efficient 13X900LA V-Belt Transmission Belts with Rubber Teeth Toothed Belt for Gear Transmission dynamo belt

80000km high quality Multi Ribbed Poly-V Belts,Poly-V-Belts/ Micro V Ribbed & Serpentine belts Drive Belts - China factory /OEM service

Teflon timing belt/OEM 941006 123RP270H HNBR+Teflon for Diesel engine belt

No noise, different teeth type timing belt, Protecting car engines, China factory HNBR/CR materials