|

Place of Origin: |

CHIAN |

|

Brand Name: |

A-DONG |

|

Model Number: |

6PK2563/5PK692 |

|

Certification: |

ISO9001/ CE /ROSH |

|

Minimum Order Quantity: |

300 |

|

Price: |

Negotiable |

|

Packaging Details: |

Standard Carton |

|

Delivery Time: |

One month / Anytime |

|

Payment Terms: |

30% deposit, 70% balance payment |

|

Supply Ability: |

20000pc/month |

6PK2563 EPDM PK Belt

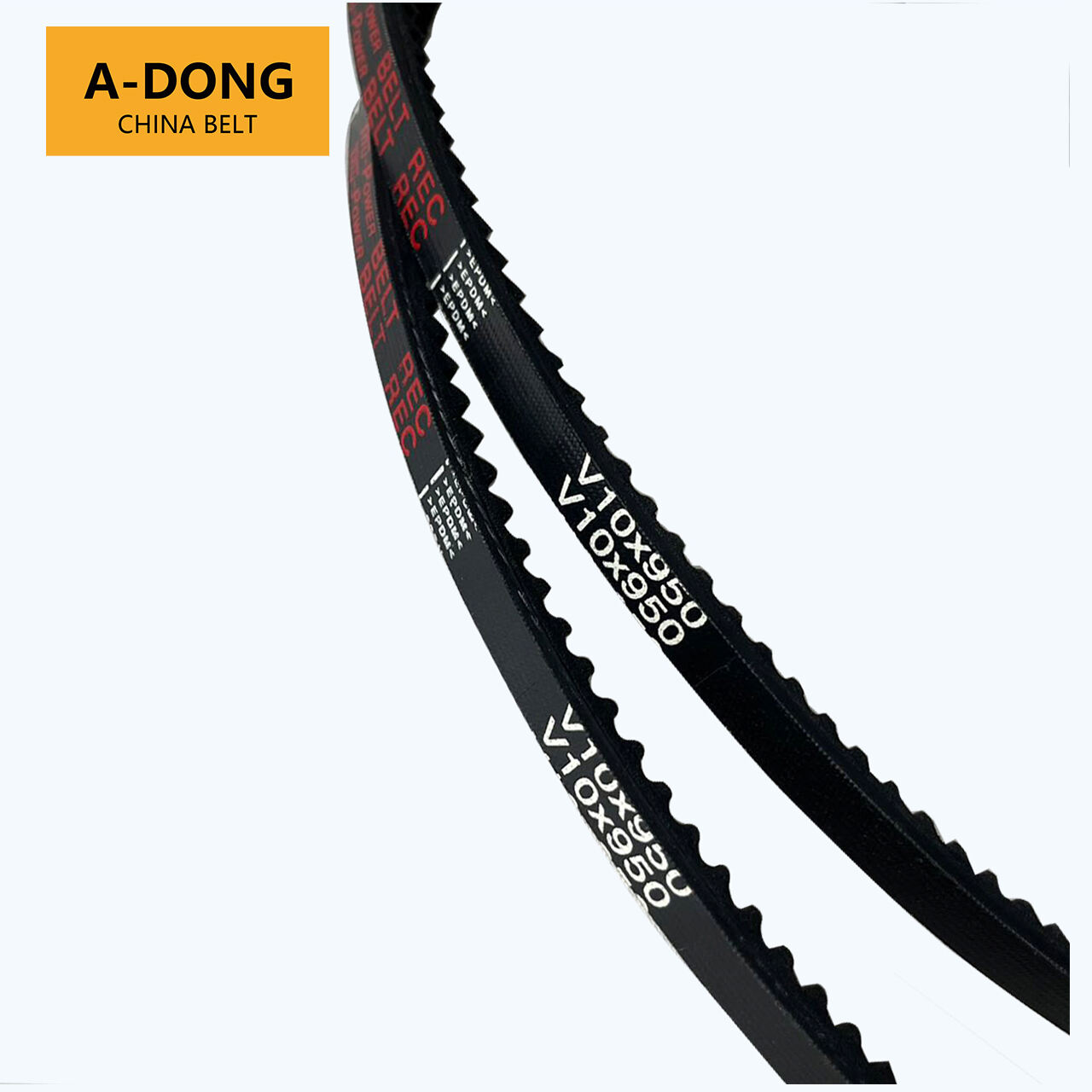

6PK2563 EPDM Multi Wedge Belt is a core component used in power transmission systems such as automobiles. "6PK" represents a combination of 6 wedge belts, "2563" refers to an effective length of 2563mm, and EPDM (ethylene propylene diene monomer rubber) is its core material.

Its core advantage is determined by the EPDM material:

Strong weather resistance: can withstand extreme temperature differences of -40 ℃ to 150 ℃, and is not afraid of high and low temperature aging.

High durability: resistant to ozone and chemical corrosion, with a service life 2-3 times longer than traditional rubber bands.

Stable transmission: The multi wedge structure fits the pulley more tightly, resulting in high power transmission efficiency and lower noise during operation.

Introduction to EPDM PK Belts

EPDM multi wedge belt is a high-performance transmission belt made mainly of EPDM rubber.

Here is a detailed introduction:

Material characteristics:EPDM has good weather resistance, ozone resistance, and chemical corrosion resistance, which enables multi ribbed belts to maintain excellent stability and durability in harsh working environments.

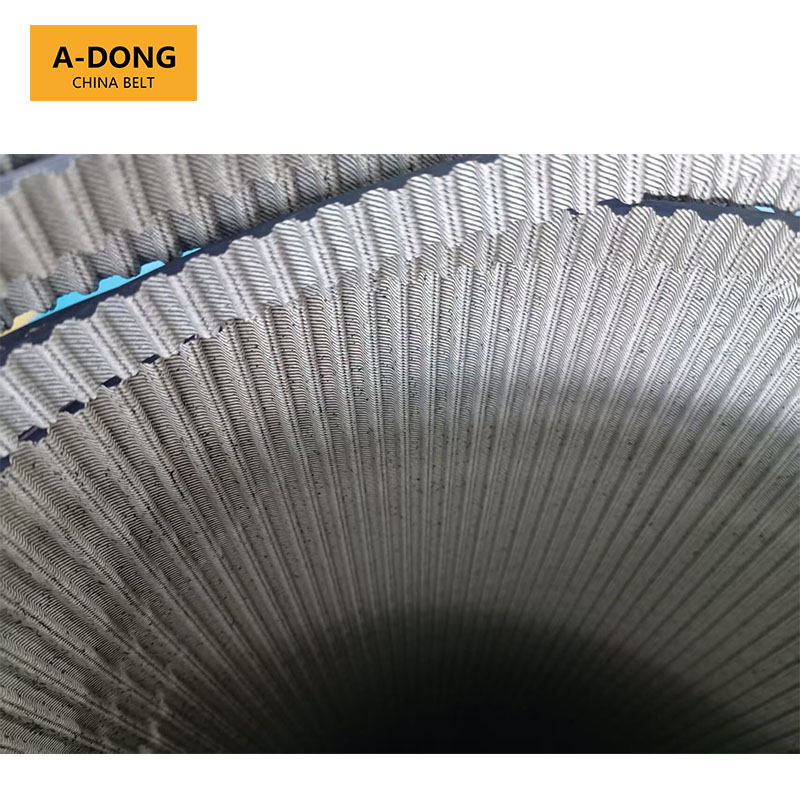

Structural features:Multiple wedge-shaped grooves are distributed on the surface of the multi ribbed belt, which increases the transmission area, effectively improves transmission efficiency, and extends the service life of the belt body by dispersing pressure.

Main advantages: It has high flexibility and can be used for small diameter pulleys; Can use one belt to drive multiple accessory system components, and the back of the belt can also complete power transmission. The double-sided multi wedge belt has a better effect; Strong ability to withstand high temperatures and work in higher temperature environments, ensuring a longer service life.

Application areas: Commonly used in automotive engine accessory transmission systems, such as air conditioning, power steering pumps, AC generators, and other equipment transmission. It is also commonly used in industrial transmission systems, air conditioning compressors, fitness equipment, packaging machinery, and other fields.

Precautions for use: When using, pay attention to matching the specifications of the pulley, avoid contact with chemical solvents, control the ambient temperature within an appropriate range, and adjust the belt tension to prevent problems such as wedge damage or abnormal noise.

What are the main applications of A-DONG Brand EPDM PK belts in?

Commonly used in automotive engine accessory transmission systems, such as air conditioning, power steering pumps, AC generators, and other equipment transmission. It is also commonly used in industrial transmission systems, air conditioning compressors, fitness equipment, packaging machinery, and other fields.

Why do we choose EPDM PK belts

Compared with ordinary materials (such as neoprene and natural rubber) PK belts, the core advantages of EPDM PK belts are better weather resistance and aging resistance and wider adaptability to the working environment, especially suitable for long-term outdoor or high-temperature working conditions.

The specific advantages can be divided into the following four points:

1. Stronger weather resistance and aging resistance: EPDM material has excellent ozone resistance, ultraviolet resistance, high and low temperature resistance, and is not prone to cracking, hardening and aging when exposed to outdoor or complex climate for a long time; However, ordinary material PK belts are prone to aging in such environments, greatly reducing their service life.

2. Wide working temperature range: EPDM material can work stably in a wide temperature range of * * -40 ℃~150 ℃ * *, and the transmission efficiency is almost not affected in high and low temperature environments; Ordinary materials (such as chloroprene rubber) usually have a tolerance range of -10 ℃~120 ℃, and are prone to slipping or belt damage at extreme temperatures.

3. Better chemical and oil resistance: EPDM has stronger resistance to common chemicals such as engine oil, coolant, acid and alkali, and is less prone to corrosion in oil contaminated environments such as car engine compartments; Ordinary material PK belts are prone to expansion and deformation when in contact with chemicals, leading to transmission failure.

4. Longer service life: Taking into account the advantages of weather resistance, temperature resistance, and chemical resistance mentioned above, the average service life of EPDM material PK tape is 1.5 to 2 times that of ordinary materials, especially in high-frequency usage scenarios such as automobiles and industrial equipment, which can reduce replacement frequency and maintenance costs.

Steering belt

Teflon timing belt/OEM 941006 123RP270H HNBR+Teflon for Diesel engine belt

80000km high quality Multi Ribbed Poly-V Belts,Poly-V-Belts/ Micro V Ribbed & Serpentine belts Drive Belts - China factory /OEM service

Generator Efficient 13X900LA V-Belt Transmission Belts with Rubber Teeth Toothed Belt for Gear Transmission dynamo belt