The following reasons cannot be applied to synchronous belts, which must have a fixed length and not be slightly different.

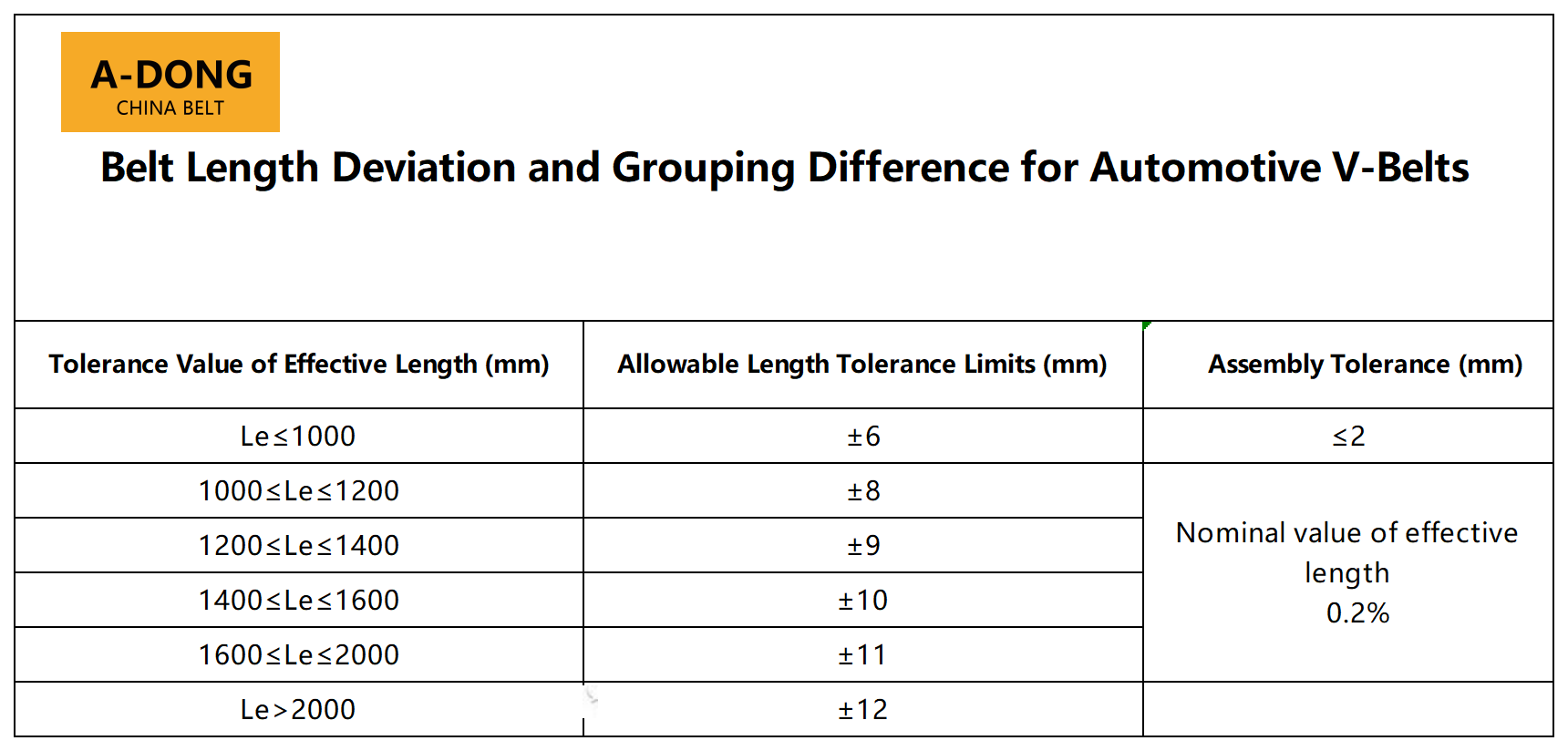

Recently, several friends have left messages asking if 6PK2155 and 2160 are compatible, and if 8PK1060 and 1062 are compatible. I want to say that they are all universal. In fact, many similar models are usually made with the same mold, such as 1062 and 1060, and factories use the 1060 mold to make them. When the factory is developing molds, large factories with strength will produce 5MM each, while factories with insufficient strength will replace them with similar models. No matter what device it is used on, the distance between the pulleys can be adjusted, which will be considered in the design, so a slight difference in belt length will not be affected.

So, what factors determine the length of the belt?

The first factor that determines the length of the belt is the selection of the mold, which is crucial as choosing the wrong one can make it difficult to achieve the standard length.

The factors that determine the length of the belt include the time it is stored in the cooling water after vulcanization and the water temperature. For example, for a 1060 mold, the belt produced may be 1060 or 1055. If two or more belts are used together, it is best to use belts from the same batch, but they still need to be assembled before use. Due to environmental factors and other influences, the length of the same model of belt from different batches of any manufacturer is not the same, and international brands are also not allowed.

The length of the belt is also determined by the thickness of the belt body. If the belt body is thick, the effective length will be shorter, otherwise it will be longer.

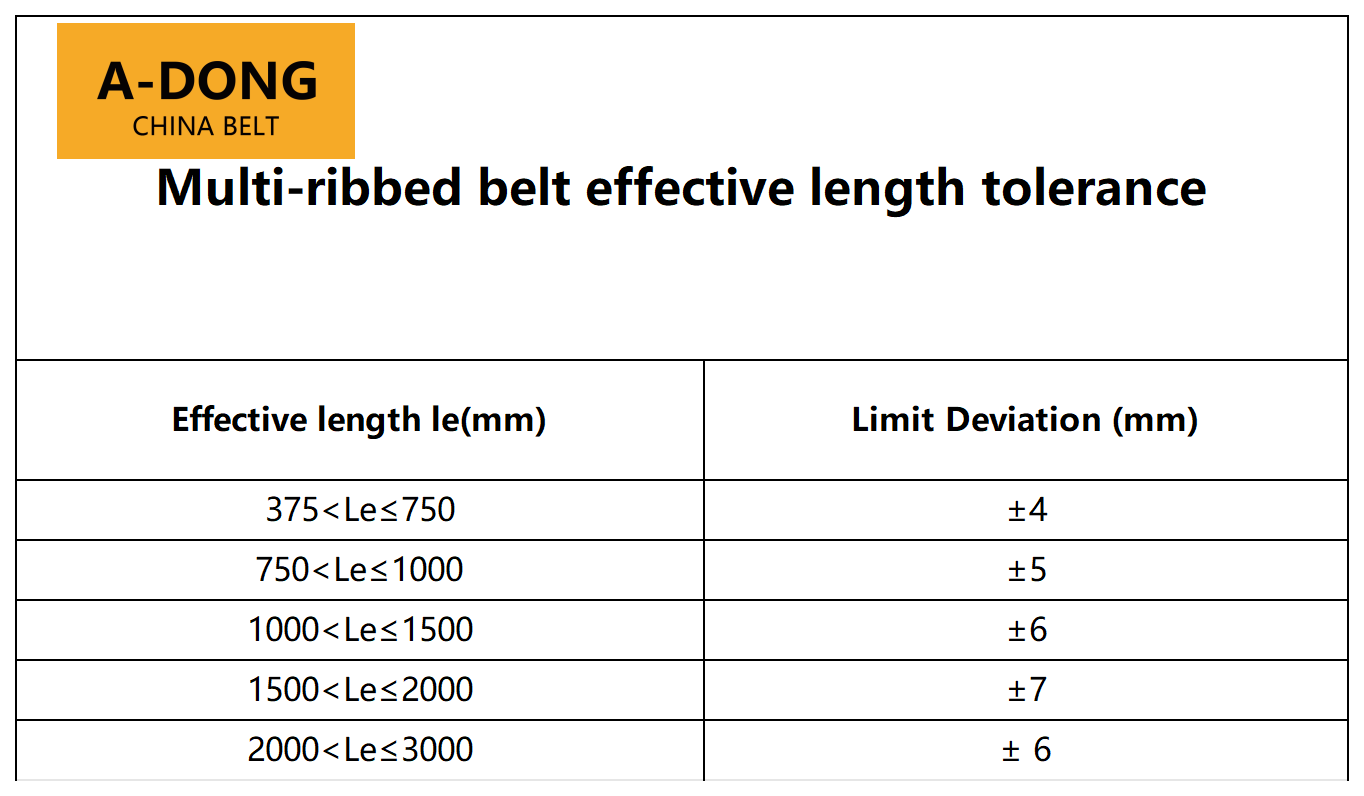

So don't talk about 2MM anymore, don't worry, it can be used.