Místo původu: |

Čína |

Název značky: |

A-DONG |

Typ modelu: |

Pk řemeny |

Certifikace: |

ISO,CE |

Minimální objednávková velikost: |

100ks každý |

Podrobnosti o obalu: |

Karton/krabice na řemeny |

Dodací doba: |

30-45 dní |

Podmínky platby: |

Wechat/Alipay/Banl |

Dodací schopnost: |

90000ks/měsíc |

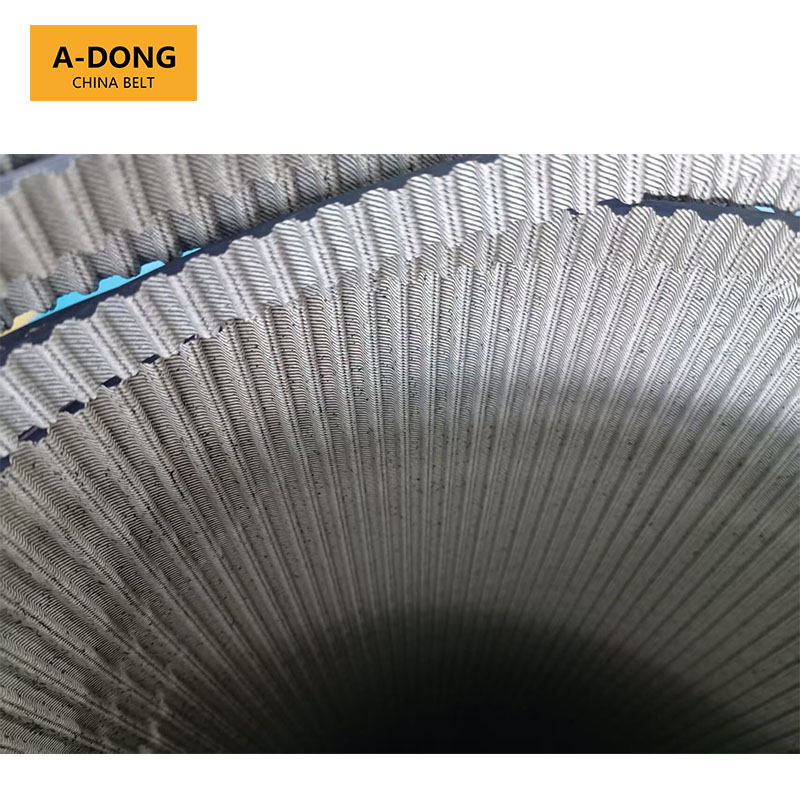

Polyklinové řemeny, známé také jako hadicové nebo víceřádkové řemeny, jsou navrženy pro vysoce účinný přenos výkonu v kompaktním prostoru. Mají na spodní straně několik podélných žeber, která zasahují do odpovídajících drážek na řemenicích. Mezi běžné profily patří J, K, L a M s teplotním rozsahem obvykle mezi -30 °C a +80 °C. Mezi hlavní výhody patří vysoké převodové poměry, snížené průměry řemenic a nižší hladinu hluku a vibrací ve srovnání s tradičními klinovými řemeny.

Polyklinový řemen, známý také jako víceklinový řemen nebo řemen s žebrováním, je typ řemene pro přenos výkonu, který je charakterizován několika podélnými žebry na své spodní straně, která zapadají do odpovídajících drážek na řemenici. Tyto řemeny kombinují pružnost plochých řemenů s vysokou výkonovou kapacitou klinových řemenů. Běžně se používají v různých aplikacích, včetně automobilových motorů, průmyslových strojů a domácích spotřebičů.

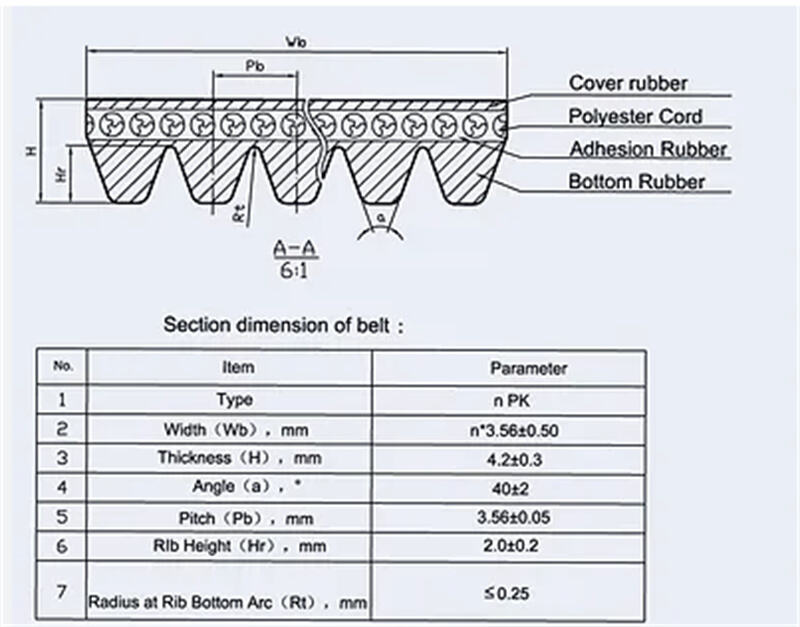

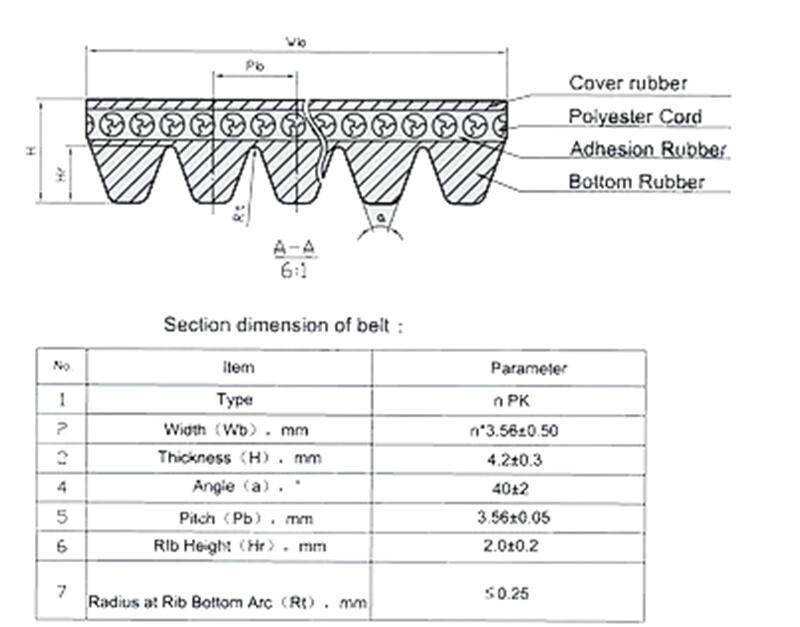

Rozteč žeber 3,56 mm

Tloušťka 4,9 mm

Lineární hmotnost (M1) 0,020 kg/m/řemen

Maximální rychlost řemene 55 m/s

Minimální průměr řemenice 50 mm

Minimální průměr mezipřevodového kola 65 mm

Předpětí při instalaci 90 až 110 N/řebro/rozpon

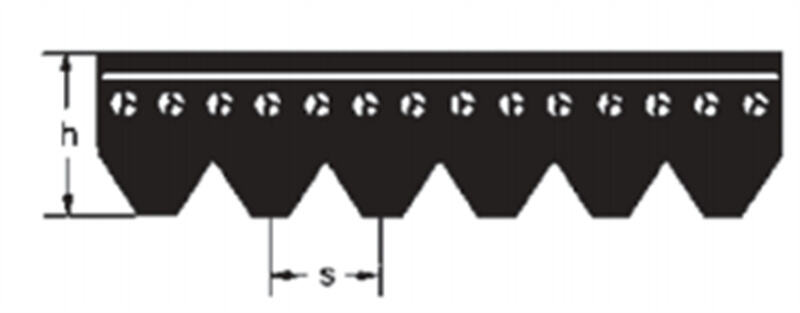

Řemeny s řebrami

|

Profilový řez |

PH |

PJ |

PK |

|

S= |

1.6 |

2.34 |

3.56 |

|

h≈ |

2.5 |

3.50 |

4.60 |

Co to je:

Typ řemenu pro přenos výkonu, který má na vnitřním povrchu více V-ovitých řeber podélného směru.

Také známé jako víceřebové řemeny nebo hadové řemeny.

Kombinuje pružnost plochých řemenů s tažnými vlastnostmi klínových řemenů.

Jak to funguje:

V-čité žebra se zapojují do odpovídajících drážek na řemenicích a přenášejí výkon prostřednictvím tření.

Zvětšená styková plocha zajišťuje lepší uchopení a snižuje prokluzování.

Klíčové výhody:

Vyšší účinnost: Zlepšený přenos výkonu díky sníženému prokluzování.

Kompaktnost: Lze použít menší řemenice a kratší vzdálenosti mezi osami.

Nižší hluk a vibrace: Hladký chod díky vícežebrovému designu.

Odolnost a delší životnost: Odolný proti opotřebení, abrazi a degradaci.

Pružnost: vhodné pro klikaté pohony a těsné ohyby.

Nižší nároky na údržbu: Minimalizuje potřebu častého napínání.

Nákladově efektivní: Dlouhodobé úspory díky prodloužené životnosti a snížené údržbě.

Běžné aplikace:

Poly-V řemene se běžně používají v různých aplikacích, včetně:

Automobilový průmysl: Pohon periferních zařízení, jako jsou alternátory, vodní čerpadla a čerpadla pro řízení.

Průmyslové aplikace: Použití v dopravních pásech, ventilátorech, kompresorech a čerpadlech.

Domácí spotřebiče: Použití v pračkách, sušičkách a vysavačích.

Cvičební vybavení: Používáno v běžeckých trenažérech a eliptických trenažérech.

Typy:

Existují různé typy Poly-V řemenů, například standardní, úzké, řemene pro proměnné otáčky a silniční řemene, z nichž každý je vhodný pro konkrétní požadavky.

Poznámka: Je důležité se při výběru správného Poly-V řemene pro vaši aplikaci seznámit s technickými specifikacemi a pokyny výrobce, aby bylo zajištěno správné montážní a servisní postupy.

Automobilový průmysl:

Řemene PK se široce používají v pohonných systémech automobilových agregátů díky své schopnosti pracovat při vysokých otáčkách, velkém převodovém poměru a kompaktním návrhům.

Průmyslové stroje:

Jsou vhodné pro různé průmyslové aplikace, včetně kompresorů, ventilátorů, obráběcích strojů, čerpadel a dalších strojů vyžadujících spolehlivý přenos výkonu.

Domácí spotřebiče:

Některé domácí spotřebiče, jako jsou pračky, mohou využívat řemeny typu PK pro přenos výkonu.

Zahradní technika:

Řemeny PK se používají také v zahradní technice, jako jsou sekačky na trávu.

Vyšší přenos výkonu:

Vícečetné řbříne na Poly-V řemenu zajišťují větší stykovou plochu s řemenicí, čímž se dosahuje vyšší účinnosti přenosu výkonu.

Nižší prokluz:

Zvětšená styková plocha minimalizuje prokluz, což vede k více konzistentnímu a spolehlivějšímu přenosu výkonu.

Zvýšená efektivita:

Menší prokluz znamená nižší ztráty energie, díky čemuž jsou Poly-V řemeny účinnější než tradiční klasické řemeny.

Kompaktní design:

Vícečetný profil umožňuje menší průměry řemenic a celkově kompaktnější pohybové systémy.

Odolnost a dlouhá životnost:

Poly-V řemene jsou často vyrobeny z odolných materiálů a dokáží odolat náročným podmínkám, což vede k delší životnosti.

Tichější práce:

Návrh a konstrukce Poly-V řemenů mohou vést k tiššímu provozu ve srovnání s tradičními V-řemeny.

Flexibilita:

Poly-V řemene jsou obecně pružnější, díky čemuž jsou vhodné pro hadové pohony s více řemenicemi.

Snížení nákladů:

Zvýšená účinnost a delší životnost mohou vést k úsporám nákladů na dlouhou trať díky nižší spotřebě energie a menšímu počtu výměn.

Odolnost proti nárazovému zatížení:

Poly-V řemene dokáží lépe zvládnout nárazové zatížení a náhlé zvýšení požadavků na výkon než tradiční V-řemene.

Antistatické vlastnosti:

Některé Poly-V řemene jsou navrženy s antistatickými vlastnostmi, což může být důležité v určitých aplikacích.

Generátor Efektivní 13X900LA klínový řemen převodové řemeny s pryžovými zuby ozubený řemen pro převodovku dynama

80000km vysoká kvalita víceklínové řemeny Poly-V, Poly-V řemeny/ mikro V-profilované a vázací řemeny hnací řemeny - továrna v Číně / servis OEM

Teflonový řemen/Originální číslo 941006 123RP270H HNBR+Teflon pro řemenový motor vznětového motoru

Bez hluku, různé typy zubů ozubeného řemenu, ochrana motorů automobilů, továrna v Číně materiály HNBR/CR